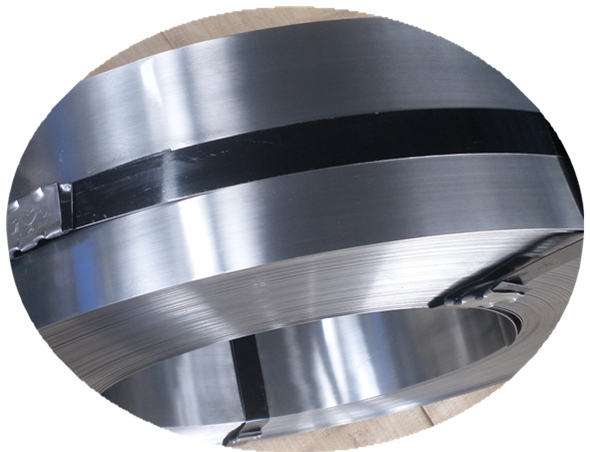

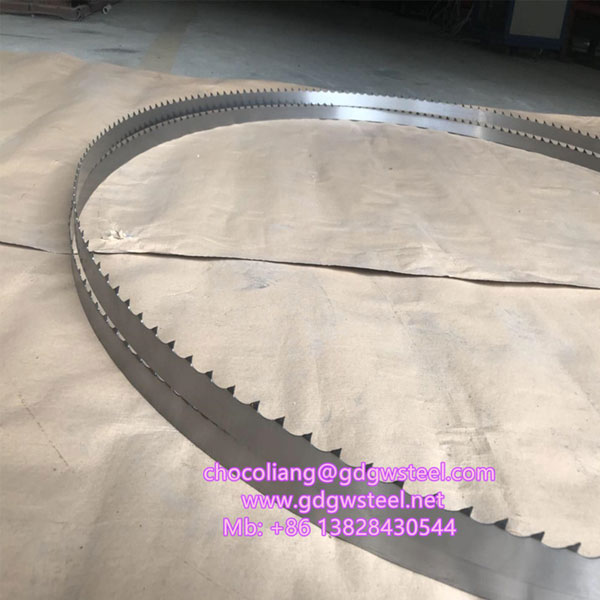

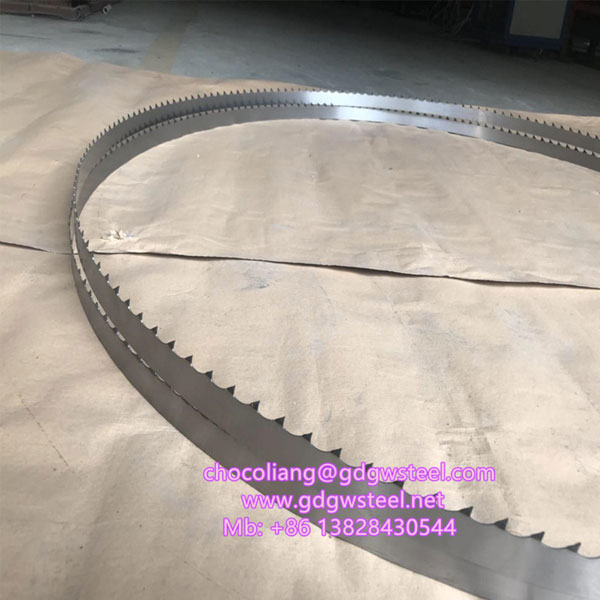

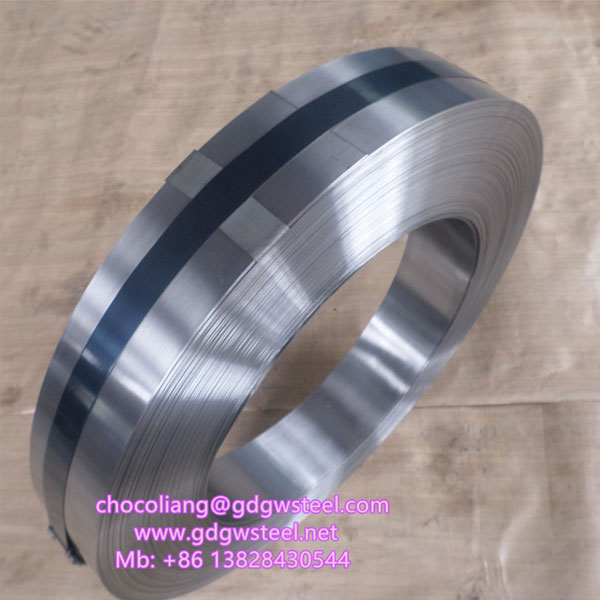

C75S hardened and tempered steel strip for bandsaw blades

Hardening and Tempering is a thermal process that strengthens steel strips through a controlled heating and cooling process.The hardening process involves heating the steel strip to above the critical transformation temperature for the given grade and then rapidly cooling. The steel strip in this condition is extremely brittle and requires further treatment in the tempering. Then strips are reheated to a lower temperature and holding it at the given temperature for a given period of time. This process isdone in an inert atmosphere to avoid oxidation. This type of steel strip has high degree of toughness and has excellent spring properties.

standard size for narrow bandsaw blade:

|

Widths mm |

Thickness mm |

|

15.oo |

0.60 |

|

20.oo |

0.60 |

|

20.oo |

0.70 |

|

25.oo |

0.60 |

|

25.oo |

0.70 |

|

30.oo |

0.70 |

|

35.oo |

0.80 |

|

40.oo |

0.80 |

|

45.oo |

0.90 |

|

50.oo |

0.90 |

standard size for width bandsaw blade:

|

Widths mm |

Thickness mm |

|

60.oo |

0.90 |

|

60.oo |

1.00 |

|

70.oo |

1.00 |

|

80.oo |

1.00 |

|

90.oo |

1.10 |

|

100.oo |

1.00 |

|

100.oo |

1.10 |

|

110.oo |

1.10 |

|

120.oo |

1.10 |

|

120.oo |

1.20 |

|

130.oo |

1.20 |

|

150.oo |

1.30 |

|

160.oo |

1.30 |

|

181.oo |

1.25 |

|

181.oo |

1.47 |

|

206.oo |

1.47 |

|

230.oo |

1.47 |

|

230.oo |

1.65 |

|

260.oo |

1.65 |

Surface for refrenced,